1. Introduction

Sheet Metal plays a crucial role in modern industry and construction. From towering skyscrapers to sophisticated electronic equipment, Sheet Metal is ubiquitous, and with its unique properties and various processing methods, it has laid a solid foundation for the development of various industries.

2. Material Characteristics of Sheet Metal

Sheet metal is made of a variety of materials, common steel, aluminum, copper and so on. Steel plate has high strength, good toughness and wear resistance, and is a commonly used material in the fields of building structure and machinery manufacturing. For example, in the construction of bridges, steel plate can withstand great weight and pressure, to ensure the stability and safety of the bridge. Aluminum is known for its light weight, corrosion resistance and good thermal conductivity, and is widely used in aerospace, automotive manufacturing and food packaging industries. In aircraft manufacturing, the use of aluminum can effectively reduce the weight of the aircraft, improve fuel efficiency, while its corrosion resistance can also adapt to the complex environment of high altitude. Copper plate has excellent electrical conductivity and antibacterial properties, commonly used in electrical equipment, piping systems and decorative areas, such as the roof of some high-grade buildings and decorative lines using copper plate, not only beautiful and generous, but also the use of its antibacterial properties to maintain environmental health.

3. Excellent processing performance

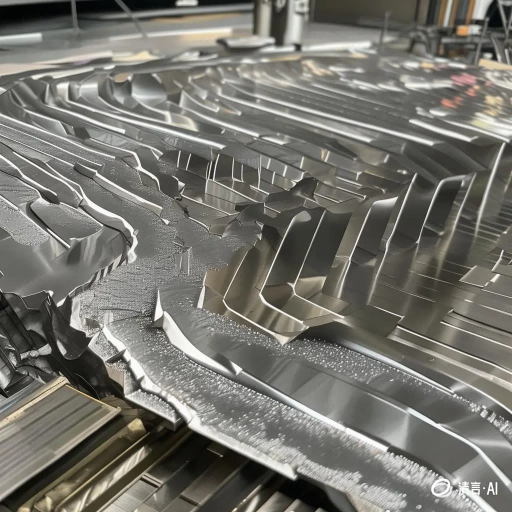

(1) Cutting and molding: Sheet Metal can be processed by a variety of cutting methods, such as laser cutting, plasma cutting, water cutting and so on. Laser cutting can realize high-precision cutting, smooth and flat cut, suitable for electronic components manufacturing and precision machining that require high precision. Plasma cutting, on the other hand, is suitable for thicker metal sheets, with fast cutting speed and high efficiency. In terms of molding, sheet metal can be made into various shapes through bending, stamping, stretching and other processes. For example, in the manufacture of automobile shells, metal sheets are processed into complex shapes through the stamping process to meet the design and functional requirements of automobiles.

(2) Welding and connection: metal plates can be connected to each other by welding, riveting, bolting and other methods. Welding can make a solid connection between the plates and ensure the integrity of the structure. Welding is one of the main methods of connection in the erection of building steel structures, welding a steel beam and steel plate together to build a strong building skeleton. Riveting is commonly used in occasions that require high strength of connection and need to be removable, such as the fuselage assembly of an airplane, and some parts are riveted to facilitate future maintenance and replacement.

(3) surface treatment: in order to improve the performance and aesthetics of sheet metal, but also a variety of surface treatment. Such as galvanized treatment can enhance the corrosion resistance of steel plate, commonly used in outdoor construction structures and some industrial equipment protection. Paint treatment can give the metal plate rich colors to meet different decorative needs, widely used in automotive painting and furniture manufacturing. Anodic oxidation treatment applies to aluminum plate, can increase the hardness, abrasion resistance and corrosion resistance of aluminum plate, but also can change its surface color, commonly used in electronic product shells and architectural decorative materials.

4. Wide range of applications

(1) Construction industry: In the construction field, Sheet Metal is used in large quantities for roofs, walls, door and window frames and other parts. Metal roofs are characterized by waterproof, durability and aesthetics, and can effectively resist the erosion of wind, rain, sunlight and other natural factors. The use of metal panels for walls adds a modern and sturdy look to the building, while also providing good fire resistance. The use of metal sheets for door and window frames can provide better safety and stability, and can be customized and designed according to different architectural styles.

(2) Automotive industry: Sheet metal is indispensable for automobile bodies, engine compartments, chassis and other components. The body is made of sheet metal, not only to ensure its strength and safety, but also to take into account the aerodynamics and aesthetics. The engine compartment sheet metal needs to have good heat resistance and sound insulation performance, in order to protect the engine and reduce the impact of noise on the interior environment. Chassis sheet metal to withstand a variety of impacts and vibrations in the vehicle driving process, to ensure the smooth running of the vehicle.

(3) electronic equipment manufacturing: sheet metal in electronic equipment is also widely used. Such as computer chassis, cell phone shell, TV backplane. Computer chassis need metal plate to provide good electromagnetic shielding performance, to prevent the internal electronic components from external electromagnetic interference. Cell phone shell using metal plate can increase the texture and durability of the phone, but also helps to dissipate heat. The TV backplane utilizes the strength and flatness of the metal plate to ensure the TV's structural stability and display effect.

(4) Home decoration: In home decoration, metal sheets can be used to make furniture, lamps, decorations and so on. Metal furniture is characterized by simplicity and fashion, solidity and durability, such as metal coffee table, dining table, chairs and so on. Lamps made of metal plate shell, you can better heat dissipation, extend the service life of the lamps, while the luster of the metal material can also add a unique charm for the home environment. Some metal decorations, such as metal sculptures, pendants, etc., can create an artistic atmosphere for home space.

5. Development trend of Sheet Metal industry

With the continuous progress of science and technology, Sheet Metal industry is also constantly developing and innovating. On the one hand, the development and application of new materials will further expand the performance and application of sheet metal. For example, the emergence of new materials such as high-strength aluminum alloy, stainless steel composite plate will play a greater role in aerospace, new energy vehicles and other fields. On the other hand, the application of digital manufacturing technology will improve the precision and efficiency of sheet metal processing. For example, the popularization of computer-aided design (CAD), computer-aided manufacturing (CAM), numerical control machining (CNC) and other technologies make the processing of sheet metal more intelligent and automated. In addition, the improvement of environmental protection requirements has also prompted the metal plate industry towards the direction of green manufacturing, research and development of more environmentally friendly processing technology and surface treatment technology, to reduce pollution of the environment.

6. Conclusion

As an important industrial and construction material, Sheet Metal plays an irreplaceable role in modern society by virtue of its rich material properties, excellent processing performance and wide range of applications. From the construction of large-scale infrastructure to the manufacture of tiny electronic components, Sheet Metal is quietly contributing its strength. As the industry continues to evolve and innovate, Sheet Metal's future is full of unlimited potential and will continue to drive progress and development across a wide range of industries, creating a better living and working environment for us. Whether you are an architect, automotive engineer or electronic equipment manufacturer, you should have a deeper understanding of Sheet Metal's characteristics and applications, fully utilize its advantages, and create more excellent works and products in your respective fields.

Copyright © 2025 Zhuhai Jingte Electromechanical Manufacturing Co.,Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist