Related Products

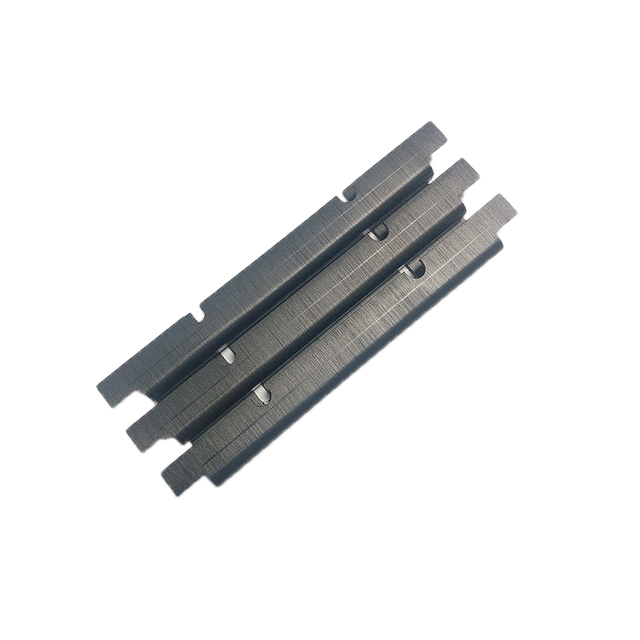

| Place of Origin: | Zhuhai, China |

|---|---|

| Product Name: | OEM |

| QC: | Full checking |

| Certification: | ISO 9001:2015 |

| Brand Name: | OEM |

Copyright © 2025 Zhuhai Jingte Electromechanical Manufacturing Co.,Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist