Company Advantages1. The design of Jingte custom plastic molding requires to consider different aspects. It is engineered for the functions of specific wearing purposes, as well as considering the common types of foot types and arch types.

2. To provide the best service, Jingte's staff has been working hard.

3. You can make special adjustments on our custom plastic molding .

4. custom plastic molding has basically comes up to the standards in terms of .

5. All incoming materials are inspected to ensure they match the quality requirement.

Products Description

Our Custom Service

Cnc Machining, Sheet Metal Fabrication, Plastic Injection Molding, Electronic Parts Assembly

Material Available

Stainless Steel:SS201,SS301,SS303, SS304, SS316, SS416, etc.

Plastic:POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc

Aluminum:Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc.

Steel:Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

Brass :C11000, C12000, C12200,C28000, C26000, C24000, C22000,C35600, C36000 etc.

Material Processing

CNC turning, CNC milling, CNC machining, Grinding,Stamping,Laser cutting,Casting,etc

Surface Treatment

Anodizing,Brushing,Galvanized,Laser engraving, Silk printing,Polishing,Powder coating,etc

Size,color and package

As per customer's requirements

Quality Inspection

IQC, IPQC,FQC,QA;ISO 9001:2015

Drawing Formats

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG),PDF,TIF,IGS, etc.

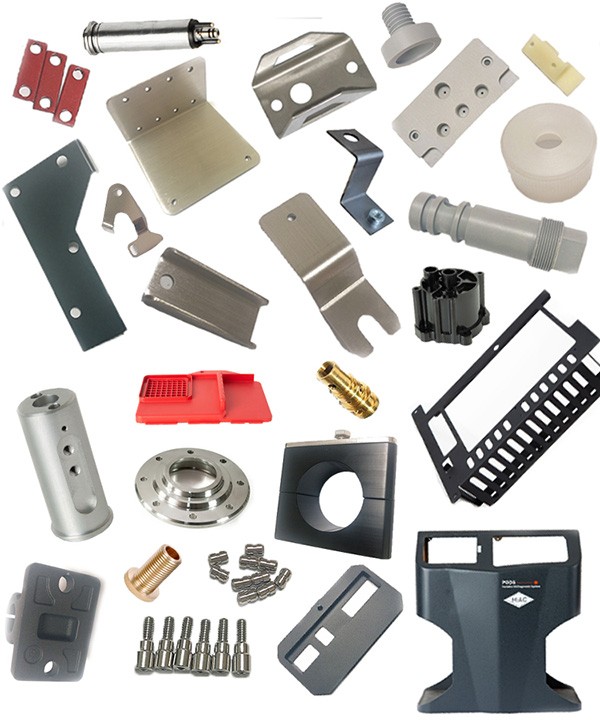

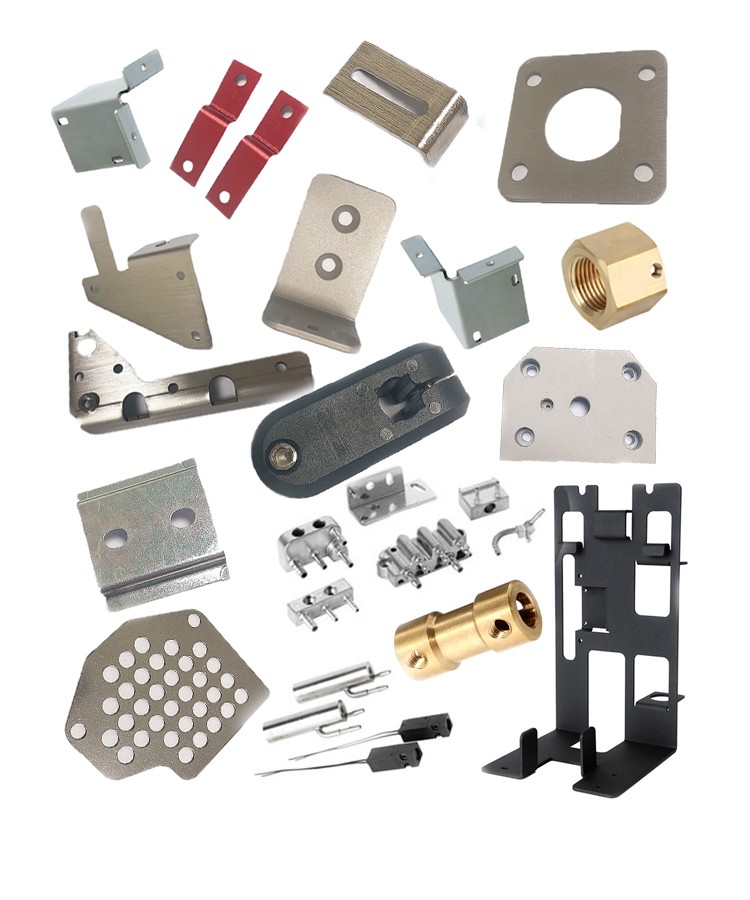

Product Photos

Company Features1. After years of solid development, Zhuhai Jingte Electromechanical Manufacturing Co.,Ltd has become one of the backbone companies that specialize in the R&D and production of custom plastic molding . The factory carries out strict quality and production management control systems. These systems require all of the incoming materials, parts, production techniques, and packaging ways to be tested and controlled to meet standards.

2. Our manufacturing center consists of production lines, assembly lines, and quality inspection lines. These lines are all controlled by the QC team to comply with regulations of the quality management system.

3. The professional technician's resources have become the key factor in our success. Those technicians are well-cultivated in terms of industry know-how and technical knowledge, which enables them to design and produce valuable and market-oriented products. We are committed to enhancing our sustainability. We’ve integrated environmental criteria into our innovation process so that every new product we launch contributes to sustainability.