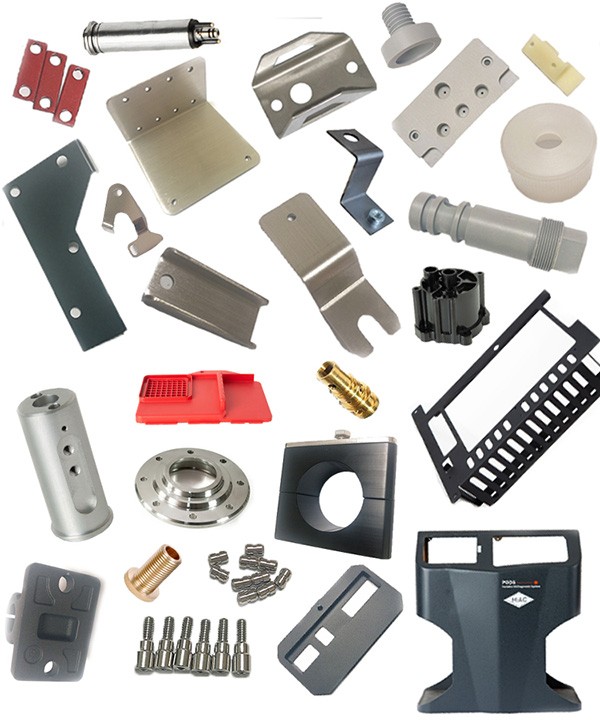

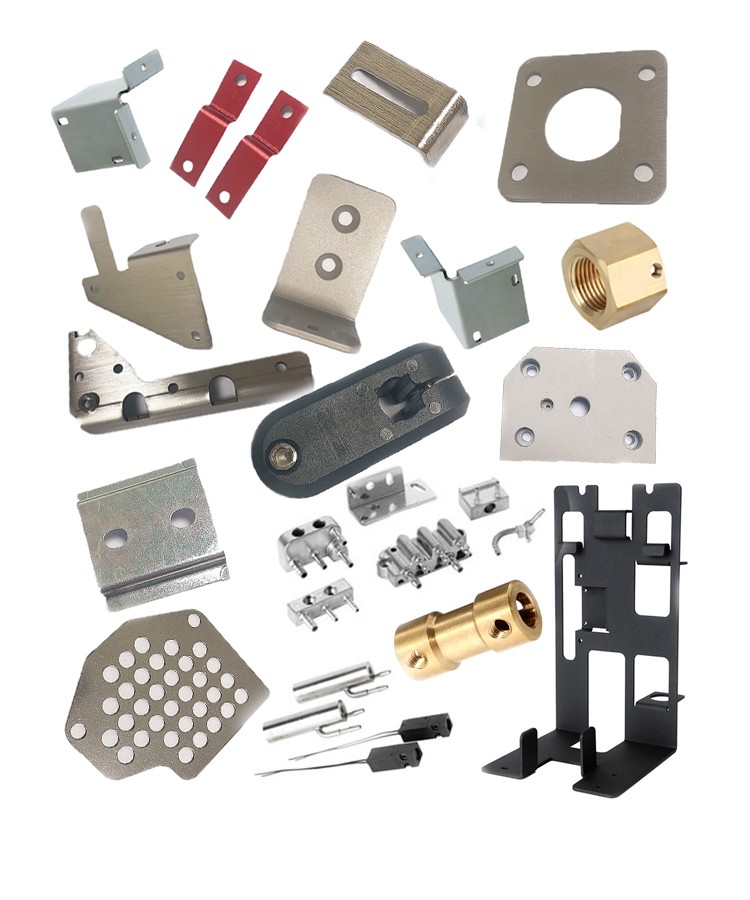

Products Description

ZhuhaiJingte

Electromechanical Manufacturing Co., Ltd.

Our Custom Service

Material Available

Stainless Steel:SS201,SS301,SS303, SS304, SS316, SS416, etc.

Plastic:POM, Peek, PMMA, ABS, Delrin, Nylon, PVC, PP, PC, etc

Aluminum:Al6061, Al6063, Al6082, Al7075, Al2024, Al5052, A380, etc.

Steel:Mild Steel, Carbon Steel, 4140, 4340, Q235, Q345B, 20#, 45#, etc.

Brass :C11000, C12000, C12200,C28000, C26000, C24000, C22000,C35600, C36000 etc.

Material Processing

CNC turning, CNC milling, CNC machining, Grinding,Stamping,Laser cutting,Casting,etc

Surface Treatment

Anodizing,Brushing,Galvanized,Laser engraving, Silk printing,Polishing,Powder coating,etc

Size,color and package

As per customer's requirements

Quality Inspection

IQC, IPQC,FQC,QA;ISO 9001:2015

Drawing Formats

Solid Works,Pro/Engineer, AutoCAD(DXF,DWG),PDF,TIF,IGS, etc.

Product Photos

Copyright © 2025 Zhuhai Jingte Electromechanical Manufacturing Co.,Ltd | All Rights Reserved

We are here to help you! If you close the chatbox, you will automatically receive a response from us via email. Please be sure to leave your contact details so that we can better assist